Energy Efficiency

Where does Energy Efficiency start?

Total cost of ownership = purchase price

+ losses

+ operational costs

+ risk to installation

+ risk to life

Become Energy Efficient

Energy Efficiency

Impedance, Resistance & Cost

What is the difference between installing either a hydraulic-magnetic or a thermal-magnetic breaker?

- Product cost

- Operational cost - it all comes down to heat.

- Impedance consists of an in phase component called resistance

- And an out of phase component called reactance

- Resistance dissipates power, while reactance returns power

- Circuit breaker losses are resistive

- Losses are heat

There is a considerable difference between thermal-magnetic circuit breakers and hydraulic-magnetic circuit breakers. The first difference is that a hydraulic-magnetic circuit breaker has a combined sensing unit: both the overload and instantaneous portions of the time delay curve are sensed by the same component.

This is not the case with thermal-magnetic circuit breakers, which use a magnetic solenoid to provide the instantaneous portion, and the heating of a bimetallic component to provide the inverse time delay portion. Aside from having many more components (and hence more opportunities for failure), the additional sensing unit has more resistance (the thermal part). This resistance is continually heated by the conducted current and this heat is ultimately lost to the atmosphere. However the electrical energy to heat this component has to have come from somewhere. Most low voltage circuit breakers are “behind” the meter and so these losses are for the customers account.

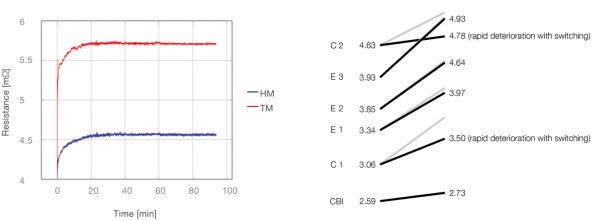

Increase in resistance

Circuit breaker resistance is dependent on heat. The hotter the device, the more electrical resistance presented by the conducting elements of the device. Eventually the amount of energy dissipated equals the amount of thermal energy generated and the device achieves thermal equilibrium. For thermal-magnetic devices, the initial (cold) resistance is higher than hydraulic-magnetic devices and so such devices heat up more. Additionally different material properties affect how much energy may be dissipated into the surrounding environment, and these temperatures increase when circuit breakers are stacked next to each other in a distribution board. There are also other factors that increase the total resistance of a circuit breakers: for example contact tip quality, which increases in resistance as the electrical contacts wear out from use.

So what does that mean to you ?

Increase in resistance (25 A)

Operational Costs

Circuit breakers, even though passive devices, still consume energy based on their resistive impedance. More resistive circuit breakers are therefore less efficient when compared with less resistive devices of the same rating. When looking at the cost of the electrical energy consumed by this component (in inflation adjusted terms), the difference in operational costs between energy efficient and less efficient circuit breakers becomes quite substantial. For an electrical device with a designed operational life span in excess of 25 years, the energy consumption difference exceeds the original purchase price of the circuit breaker.

The total cost of ownership for a circuit breaker consists of the purchase price, and the operational costs, which is dependent on the efficiency of the circuit breaker. There are however two hidden costs: the first being the risk to the installation that may be present if cheap non-compliant circuit breakers are installed. These devices may fail and ignite under normal load conditions! A risk to an installation also implies a risk to the lives of those who use and occupy the buildings into which these non-compliant circuit breakers are installed.

ENERGY EFFICIENT

Labelling scheme

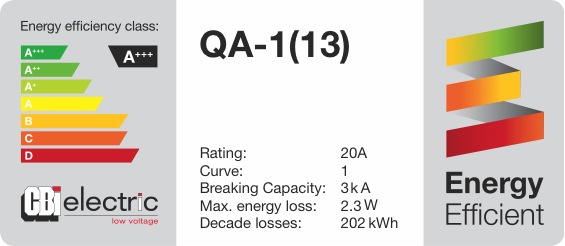

The only way to assess the amount of energy consumed by a circuit breaker is to test it. Depending on the resistivity of the circuit breaker, it is possible to classify the energy consumption and class the product. Additionally it is possible to determine the amount of electrical energy the device consumes over the course of a decade, and from this value it is possible to estimate the operational costs of the device. Higher resistive devices are more expensive to operate.

LOOK OUT FOR THIS LABEL